Most Popular Products

|

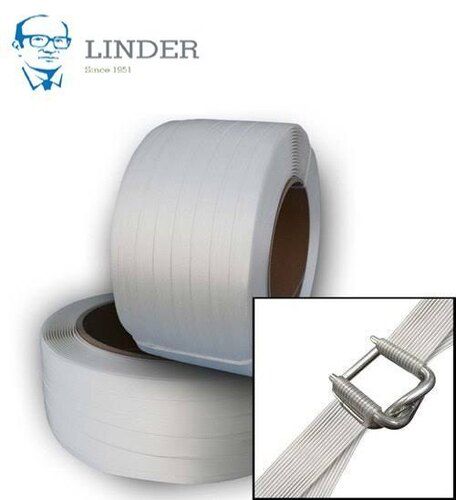

Composite Strapping

MOQ : 50 Units

Composite Strapping Specification

- Size

- 13 mm, 16 mm, 19 mm, 25 mm, 32 mm (widths available)

- Thickness

- 0.5 mm to 1.5 mm (varies by grade)

- Usage & Applications

- Securing heavy pallets, bundling materials, cargo tie-down, logistics, construction, and industrial packaging.

- Design Type

- Plain, woven pattern

- Color

- White

- Dimension (L*W*H)

- Custom roll lengths; W: 13 mm to 32 mm

- Product Type

- Aerosol Products

- Product Form

- Strap/Roll

- Material

- Polyester composite fiber

- Shape

- Round

- Surface

- Polished

- Application

- Heavy duty packaging, transport of industrial goods, load securing.

- Corrosion Resistance

- Yes

- Elongation

- 8% - 12%

- Reusable

- Yes, can be retensioned

- Closure Method

- Compatible with galvanized steel buckles

- Break Strength

- 350 kg to 2200 kg (depending on width and grade)

- Tensile Strength

- High tensile, suitable for heavy load securing

- Weight per roll

- Varies by size, approx. 8 kg to 10 kg

- Weather Resistance

- UV and moisture resistant

- OEM/ODM customization

- Available

Composite Strapping Trade Information

- Minimum Order Quantity

- 50 Units

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 1000 Units Per Week

- Delivery Time

- 5 Days

- Main Domestic Market

- All India

About Composite Strapping

Reserve your supply of our Monumental Composite Strapping, favored by industry leaders and lauded in favorable reviews for its inestimable strength and versatility. Crafted from valuable polyester composite fiber, each roll delivers a break strength ranging from 350 kg up to 2200 kg, tailored to your securing needs. Its polished surface and round shape enhance durability while resisting corrosion and weather. Grab this high-tensile strap for heavy-duty packaging, logistics, and construction. Reusable and compatible with galvanized steel buckles, this valuable solution stands out as an industry benchmark, whether for industrial bundling or safeguarding cargo.

Composite Strapping: Key Features and Ideal Use

Composite Strapping stands out for its high break strength, ranging from 350 kg to 2200 kg, and substantial elongation (8%12%), ensuring reliable tensioning. Its UV and moisture resistance make it optimal for outdoor and industrial use. The strap is suited for securing heavy pallets, cargo tie-down, and bundling in logistics and construction. Compatible with galvanized steel buckles and reusablewith retensioning abilityit delivers dependable performance for heavy load applications and stringent packaging requirements.

Payment Terms, Certifications, and Delivery Process

Our Composite Strapping is available with flexible payment terms to streamline order completion and goods transport. We hold relevant industry certifications for quality and safety, ensuring each roll meets high standards. Delivery times are prompt for both OEM/ODM and regular orders, supported by efficient logistics networks across India. From order placement to distribution, we prioritize seamless logistics, dependable supply, and timely delivery to help you secure industrial goods without delay.

Composite Strapping: Key Features and Ideal Use

Composite Strapping stands out for its high break strength, ranging from 350 kg to 2200 kg, and substantial elongation (8%12%), ensuring reliable tensioning. Its UV and moisture resistance make it optimal for outdoor and industrial use. The strap is suited for securing heavy pallets, cargo tie-down, and bundling in logistics and construction. Compatible with galvanized steel buckles and reusablewith retensioning abilityit delivers dependable performance for heavy load applications and stringent packaging requirements.

Payment Terms, Certifications, and Delivery Process

Our Composite Strapping is available with flexible payment terms to streamline order completion and goods transport. We hold relevant industry certifications for quality and safety, ensuring each roll meets high standards. Delivery times are prompt for both OEM/ODM and regular orders, supported by efficient logistics networks across India. From order placement to distribution, we prioritize seamless logistics, dependable supply, and timely delivery to help you secure industrial goods without delay.

FAQs of Composite Strapping:

Q: How do I determine the correct width and grade of composite strapping for my load securing needs?

A: Select the composite strapping width and grade based on the weight and type of goods. For lighter loads, a lower break strength suffices; for heavy pallets, choose wider grades with higher break strength (up to 2200 kg) to ensure reliable and safe load securing.Q: What makes composite strapping suitable for outdoor and industrial applications?

A: Composite strapping is UV and moisture resistant, meaning it wont degrade under sun exposure or humid conditions. Its polyester composite material and corrosion-resistant properties ensure longevity and safety for outdoor logistics and industrial packaging.Q: Where can composite strapping be used most effectively?

A: This strapping is ideal for securing heavy pallets, bundling industrial materials, cargo tie-down during transport, and packaging in construction industries. Its versatility caters to various heavy-duty load securing requirements.Q: When is it beneficial to choose reusable composite strapping over traditional alternatives?

A: Reusable composite strapping is advantageous when frequent retensioning is required or when high break strength is needed in shifting or long-term storage situations. Its ability to be retensioned and reused offers both economic and environmental benefits.Q: What is the process for customizing composite strapping with OEM or ODM services?

A: Customers can specify their required dimensions, strength, closure type, and design patterns. OEM/ODM customization options include roll length, width, thickness, and color, allowing distributors, manufacturers, or traders to match the strapping to exact project needs.Q: How does the closure method enhance the performance of composite strapping?

A: The strapping is compatible with galvanized steel buckles, which provide secure closures and maintain tension under heavy loads. This ensures durable locking and efficient cargo safety during transport or storage.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Polyester Strapping Category

Polyester Baling Press Strapping

Minimum Order Quantity : 50 Units

Shape : Round

Application : Pest Insecticide

Surface : Plain

Product Form : Foam

Polyester Strapping

Price 70 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Application : Pest Insecticide

Surface : Polished

|

Yuv Sicher System

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry